Among the many remarkable blades found across the world, the Japanese katana stands alone in its legendary reputation for achieving what is often described as the perfect trinity of performance: “unbreakable, unbending, and razor-sharp.”

But why is it that only the Japanese katana has achieved this extraordinary balance?

When we compare the katana with other historical swords from around the world, a striking difference becomes immediately apparent: while most swords have straight blades, only the Japanese katana features a distinct curvature.

It turns out that this subtle yet elegant curve holds the key to the katana’s superior performance.

In this article, we explore the hidden function behind the curvature of the katana—an innovation so refined, it can only be described as a miracle of craftsmanship.

Why Can the Katana Truly Be “Unbreakable, Unbending, and Razor-Sharp”?

The phrase “unbreakable and unbending” sounds ideal—especially for a weapon. However, in the world of materials science, these two traits are generally considered contradictory.

This is because the harder a piece of steel becomes, the more resistant it is to bending—but at the same time, it becomes more brittle and prone to breaking. On the other hand, increasing its toughness to prevent breakage usually results in a material that bends more easily.

So how did the ancient Japanese swordsmiths accomplish what seems to defy the very nature of steel?

The answer lies in their ingenious use of material combination and precise control of cooling rates—techniques refined over centuries of craftsmanship.

Let us explore each of these elements in turn.

Combining Materials

A Harmonious Fusion of Hard and Soft Steel

One of the key techniques that make the contradictory qualities of “unbreakable and unbending” possible is the strategic combination of different types of steel.

In traditional Japanese sword-making, the blade’s core—known as shingane—is forged from a softer, more ductile steel. This inner core is then enveloped by a hard outer steel jacket called kawagane, which provides the necessary sharpness and resistance to wear.

By combining a resilient interior with a hard exterior, the sword achieves a perfect balance between flexibility and cutting power.

This sophisticated method is known as tsukurikomi, or structural composition, and it represents one of the most refined metallurgical techniques in traditional Japanese craftsmanship.

Sorting Steel by Hardness

Now, how exactly are the hard and soft steels separated from the same piece of tamahagane steel?

The hardness of steel is influenced by its carbon content. Higher carbon content results in harder steel, while lower carbon content makes the steel softer. This difference is used to sort the steel based on its brittleness: harder steel with more carbon tends to crack more easily.

First, the tamahagane is heated and hammered into thin plates just a few millimeters thick. Then, by rapidly cooling these plates in water—a process called quenching—the high-carbon, hard sections naturally crack and break apart.

Next, the blacksmith hammers the steel fragments with a small mallet: the pieces that crack are identified as high-carbon, hard steel used for the outer jacket, kawagane; the pieces that remain intact are lower-carbon, softer steel designated for the core, shingane.

Through this careful sorting process, the ideal combination of hard and soft steel is achieved for crafting an exceptional katana.

The Importance of Repeated Forging

Afterwards, the steel undergoes a process called repeated forging. The steel is heated and hammered flat, then scored and folded back repeatedly.

This process removes impurities that cause brittleness and also adjusts the carbon content. Generally, the carbon content decreases with each cycle of folding and forging.

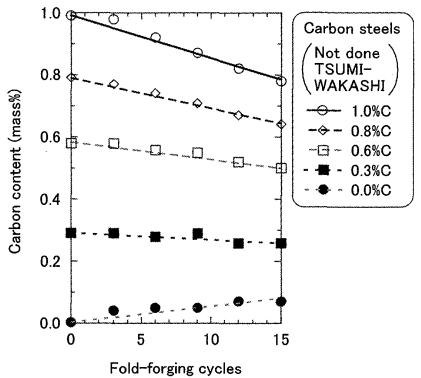

This figure shows how the carbon content changes after repeated forging of carbon steel with initial carbon percentages of 0%, 0.3%, 0.6%, 0.8%, and 1.0%.

Except for the 0% carbon steel, it can be seen quantitatively that the carbon content decreases progressively as the number of forging cycles increases.

Ancient swordsmiths skillfully used this characteristic to regulate the carbon content. Additionally, with continued forging, the steel forms distinct layers.

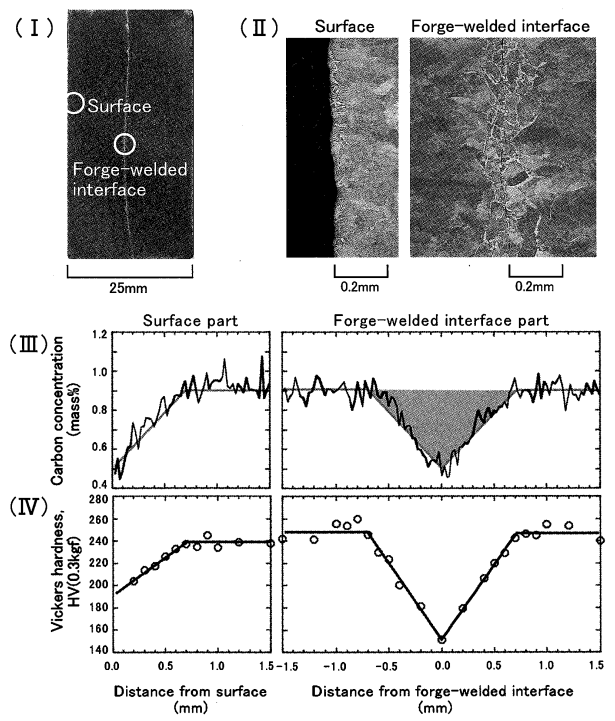

Focusing on these layered structures, the following results about carbon content and hardness were obtained.

Graph (III) shows the carbon content, revealing that the carbon content decreases at the surface and folded layers of the steel.

Next, graph (IV) presents hardness measurements using the Vickers hardness test. There is a strong correlation with graph (III), confirming that areas with reduced carbon content are softer.

At the time, accurately measuring carbon content was impossible, let alone during the forging process. Swordsmiths relied on empirical knowledge to skillfully adjust carbon levels and achieve ideal hardness—a truly remarkable feat.

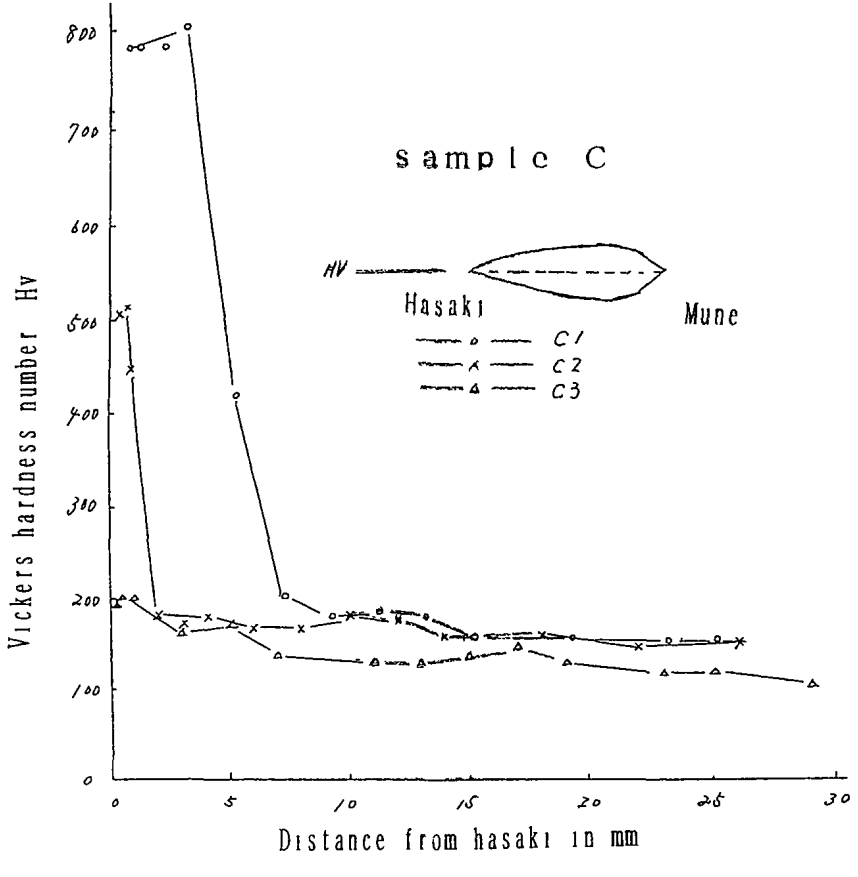

When measuring the hardness of an actual finished katana, the following results were obtained:

The left side of the diagram corresponds to the cutting edge, and the right side to the back of the blade. It shows that the edge is hard, gradually softening toward the spine.

This confirms that the katana is crafted by skillfully combining materials with different hardness levels.

Next, let’s explore the other key factor behind the katana’s “no breakage, no bending” characteristic: control of the cooling speed.

Controlling the Cooling Rate During Quenching

What Is Quenching?

Once the construction process (known as tsukurikomi) is complete—combining hard kawagane (outer steel) and soft shingane (core steel), heating and hammering them into the shape of a katana—the sword undergoes a critical step called quenching.

In this process, the katana, heated to around 800°C, is rapidly cooled by immersing it in water. This sudden cooling transforms the internal structure of the steel, giving the blade the specific physical characteristics required for a functional and durable Japanese sword.

How Steel Changes with Temperature

Steel undergoes structural changes depending on its temperature.

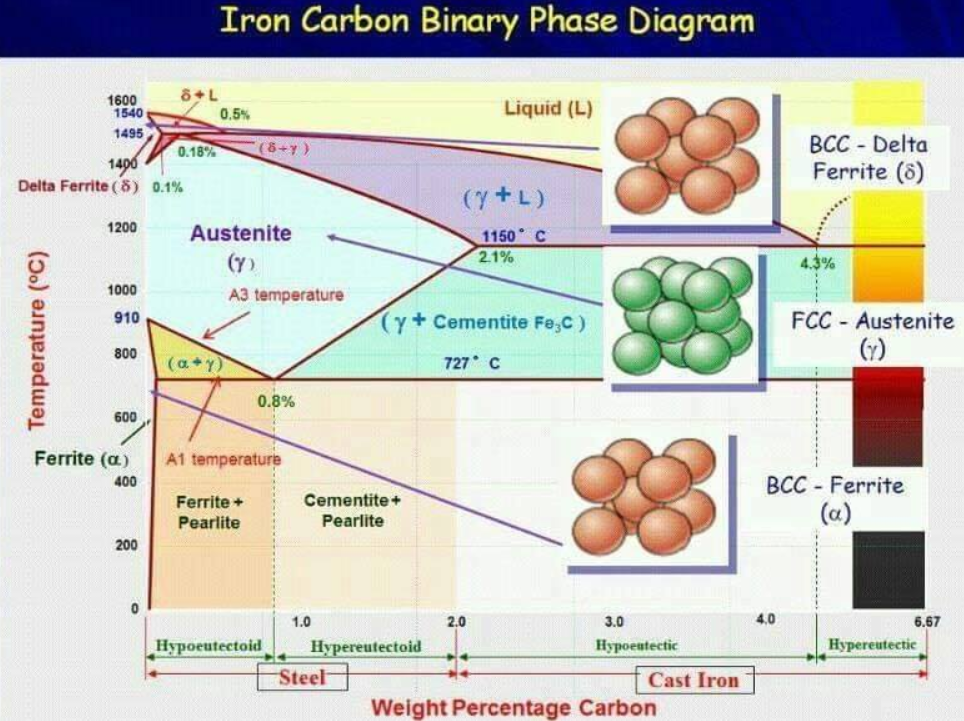

At room temperature, if the carbon content is below 0.765%, the microstructure consists of ferrite + pearlite. When the carbon content exceeds 0.765%, the structure becomes pearlite + cementite. Ferrite contains very little carbon and is a soft, easily deformable phase.

As the steel is heated beyond 727°C, a new phase known as austenite appears. This structure can dissolve up to 2% carbon and does not exist at room temperature.

Unlike ferrite, which has a body-centered cubic (BCC) crystal structure and can dissolve only a small amount of carbon, austenite has a face-centered cubic (FCC) structure, allowing it to hold significantly more carbon.

As austenite cools and transforms back into ferrite, the excess carbon that cannot be retained in the BCC lattice is expelled and precipitates as cementite (iron carbide).

However, if the austenite is cooled rapidly, it transforms into a structure called martensite. In this rapid cooling process, carbon atoms become trapped in a supersaturated BCC lattice, distorting the crystal structure. This distortion is what gives martensite its exceptional hardness.

This hardness of martensite is precisely what we aim to utilize for the cutting edge of the katana. Therefore, it becomes necessary to rapidly cool only the edge to form martensite, while the rest of the blade cools more slowly. But how is such precise control achieved?

Controlling the Cooling Rate

During the quenching process of a Japanese katana, a special clay mixture known as yaki-ba-tsuchi—a combination of clay, charcoal powder, and other materials—is applied to the blade before it is heated and then cooled in water.

By applying a thinner layer of this mixture to the edge, which is intended to become harder, and a thicker layer to the rest of the blade, craftsmen are able to control the cooling rate of different parts of the sword.

This application of clay not only regulates how quickly each part cools, but also determines the shape of the hamon—the temper line that appears on the blade after quenching. Thus, the use of yaki-ba-tsuchi is crucial both functionally and aesthetically, giving each sword its unique character and performance.

What Does the Unique Curvature of the Katana Signify?

A Byproduct of Controlled Cooling?

It is often said that the Japanese katana is the only bladed weapon in the world made from layered materials that features a distinct curvature. So why does the katana have this unique curve?

In fact, the curvature is believed to be a byproduct of the quenching process we discussed earlier.

As we’ve seen, the edge of the blade is rapidly cooled, causing it to transform into martensite, while the spine (mune) cools more slowly, resulting in structures like pearlite, cementite, and ferrite. Since martensite has a greater specific volume than these other structures, the blade naturally bends toward the spine as it cools.

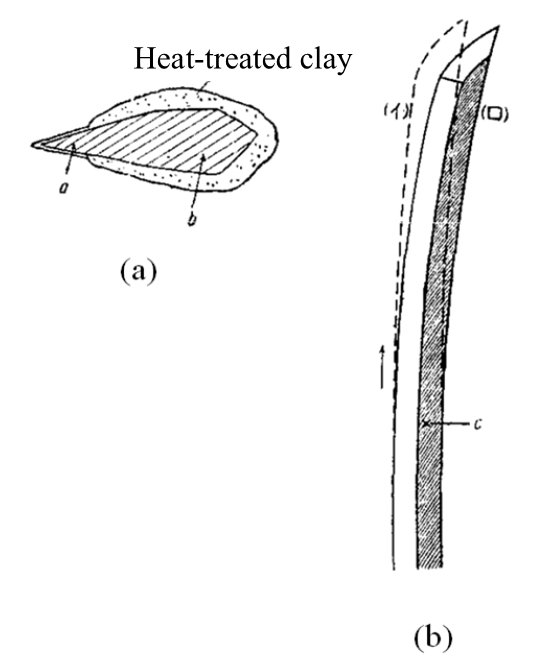

In (a), a thin layer of yaki-ba-tsuchi is applied to the edge of the blade, causing rapid cooling and martensitic transformation. This transformation leads to expansion, resulting in the characteristic curvature toward the spine, as shown in (b). This explains how the unique curve of the katana is formed.

There are various theories regarding the cause of this curvature, but one notable piece of evidence supporting the martensitic expansion theory is this: when a katana-shaped test specimen made from austenitic stainless steel (which does not undergo martensitic transformation) was quenched, no curvature occurred. This lends strong credibility to the idea that the katana’s curve is the result of martensitic transformation and its associated volume expansion.

Curvature Enhances Toughness

The curvature of the katana is not merely a byproduct of the quenching process—it actually contributes to the blade’s mechanical strength.

As the edge of the blade expands due to the martensitic transformation, it is constrained by the spine (which does not expand as much). This constraint forces the edge to bend outward, creating the distinctive curvature and inducing a significant compressive residual stress in the cutting edge.

This compressive stress extends across the entire surface of the blade, enhancing the toughness of the katana. Toughness refers to the metal’s resistance to cracking or fracturing under external forces—a key quality in ensuring the blade doesn’t easily break or deform.

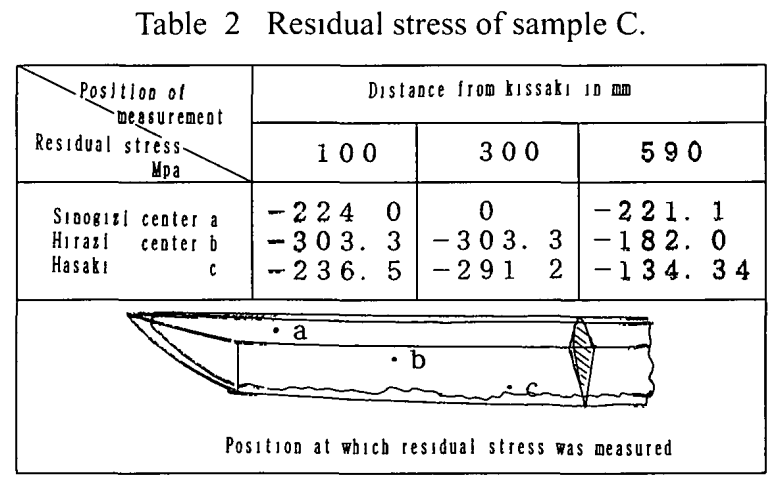

Take a look at the experimental results measuring the residual stress in a Japanese katana:

While the measurement at the point 300mm from the tip (kissaki) showed unexpectedly low compressive residual stress, the rest of the blade consistently exhibited compressive stress across its surface.

This residual compressive stress, induced by the curvature, is another crucial factor that enables the katana to achieve its legendary combination of flexibility and unbreakable strength—truly fulfilling the ideal of a blade that “does not bend, does not break, and cuts well.”

Curvature Enhances Cutting Performance, Too!?

But wait—the benefits of curvature don’t stop there. Incredibly, the curvature of a Japanese katana also contributes directly to its cutting performance.

When slicing through a material, incorporating a pulling or drawing motion—known as hikikiri in Japanese—makes cutting significantly easier. (If you’re interested in the science behind sharpness itself, we invite you to read our detailed article on the The Mystery of Authentic Katana Sharpness.)

Thanks to its curvature, the katana naturally facilitates this drawing cut far more effectively than a straight-edged blade. In short, the world-renowned sharpness of the Japanese katana is partly due to its curve.

From a practical perspective, the curvature of the katana also enables swift drawing and cutting in one fluid motion—a critical advantage in combat. Imagine a mounted warrior or a duel between samurai: a single, decisive stroke drawn directly from the scabbard could determine the outcome. The katana’s curve makes such a strike not only possible, but natural and efficient.

As a side note, the author is a fan of the Japanese samurai manga Rurouni Kenshin, in which the protagonist’s ultimate technique is a powerful battōjutsu (sword-drawing technique) unleashed directly from the scabbard. I can’t help but wonder whether real historical samurai also relied on such decisive, lightning-fast blows in moments of critical battle.

The intelligence and craftsmanship embedded in the Japanese katana is nothing short of astonishing—from material combinations and precise control of cooling rates, to the structural curvature that enhances both toughness and sharpness, and finally to combat techniques that take full advantage of its unique form.

Truly, the Japanese katana is a miracle of metallurgy and martial design. I’m excited to keep exploring the fascinating world of the Japanese sword — a cultural and martial treasure found nowhere else in the world.

References

Naohiko Sasaki and Tadashi Momono(2007). Changes in Carbon Content of Materials of the Japanese Sword under Traditional Forging Process

Hideo Hoshi and Minoru sasaki (2007). Metallurgical Research on Japanese Swords – Focusing on Swords for Practical Use –

Kyozo Arimoto(2017). Changes in Research on the Curvature Phenomenon of Japanese Swords

Takuya Oba(2019). Metal Crystallography from Viewpoint of Tatara

STUDYMETA.COM