The Japanese katana is often said to be the only blade in the world that truly achieves the ideal trifecta: unbreakable, unbending, and razor-sharp.

What makes this possible? Many experts point to the katana’s distinctive curvature. But beneath this elegant form lies an astonishingly complex process involving the combination of materials with different hardness levels and the precise control of cooling speeds during heat treatment. These techniques together create a blade of exceptional sharpness and durability—arguably unmatched anywhere in the world.

For more details on the functional role of curvature, see our previous article:

Curved for a Reason: The Hidden Function of Authentic Katana’s Shape

That such a feat of craftsmanship could be achieved in a time without modern equipment is nothing short of miraculous.

In this article, we delve into the metallurgical structure inside the blade to uncover what truly happens at the microscopic level as a result of this extraordinary manufacturing process.

Learning About Blade Metallurgy from Japanese Kitchen Knives

Comparison of Knife Structures

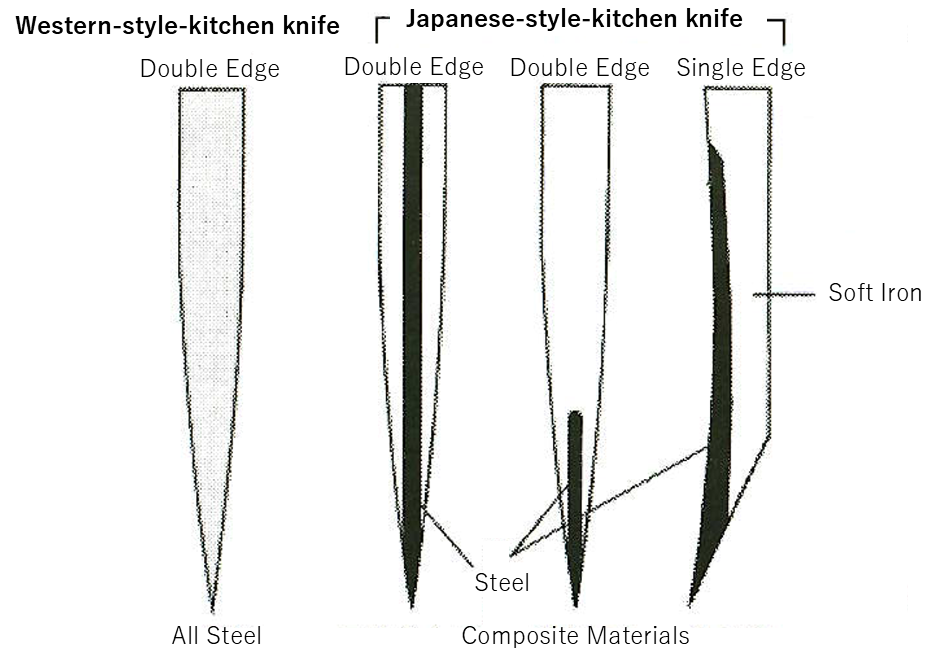

The craftsmanship of the Japanese sword lives on in modern times. For example, while Western kitchen knives are typically made from a single type of steel throughout, many Japanese knives are carefully forged using a combination of different materials.

The concept behind Japanese knives follows the same principle as the katana: a soft steel core provides toughness, while a hard steel edge ensures sharpness and cutting performance.

As shown here, Western knives are generally made from a uniform piece of steel. In contrast, Japanese knives come in several layered configurations:

- three-layer laminates with soft iron and hard steel,

- A soft-iron body with a steel blade,

- or soft iron bodies with hard steel applied to one side.

These variations reflect a deep tradition of metallurgical wisdom designed to achieve an ideal balance between strength, sharpness, and resilience.

Microstructural Analysis of a Japanese Kitchen Knife

Now, let’s take a closer look at the internal structure of a Japanese kitchen knife as observed under a microscope.

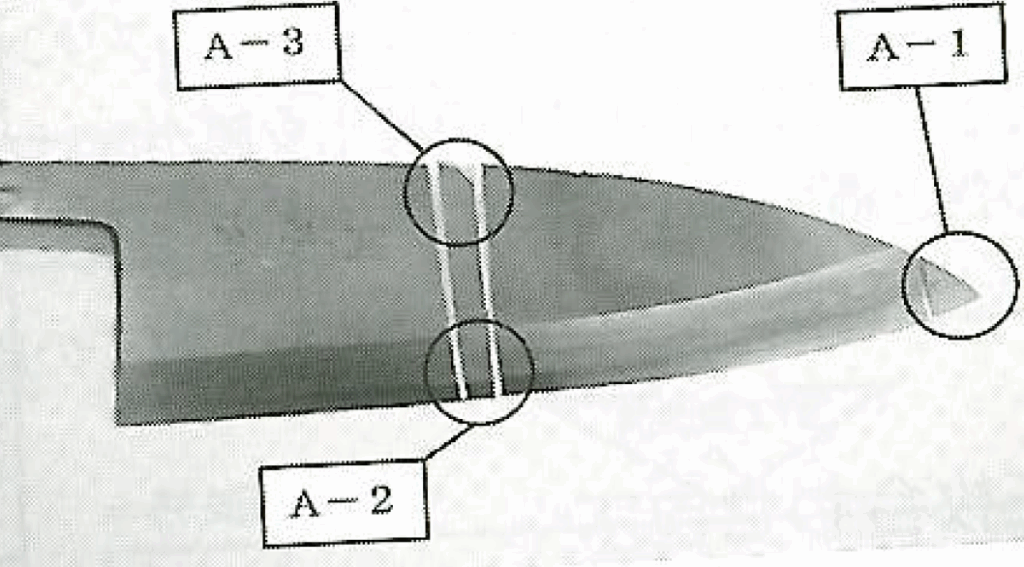

In this study, a deba bōchō was used, one of the most popular types of single-bevel Japanese kitchen knives.

Samples were taken from both the center of the blade and the tip (kissaki) for analysis.

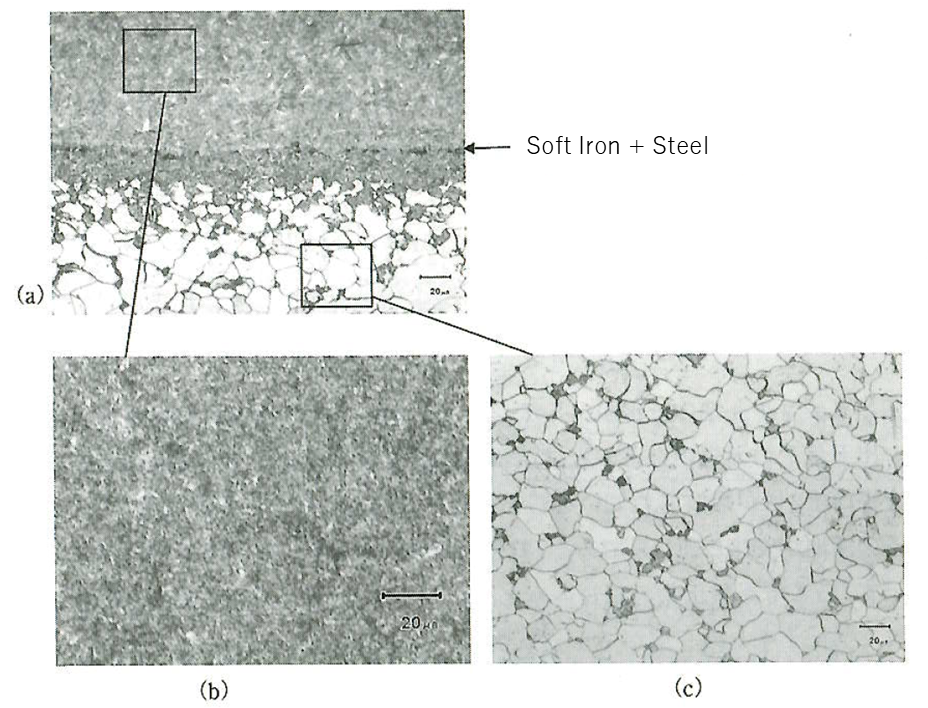

This image shows a microscopic view (500x magnification) of the sample taken from the blade tip.

In photo (a), we can clearly see two distinct regions: the upper section made of hard steel and the lower section made of soft iron.

Photo (b) is a magnified view of the hard steel area. The carbon content here is approximately 1.1–1.3%, and the primary phase is martensite.

Photo (c) shows the soft iron region, which exhibits a ferrite + pearlite structure, with pearlite comprising around 5–8% of the observed area.

At the interface between the steel and soft iron, carbides (likely Fe₃C) can be seen. These appear to be the result of carbon diffusion from the high-carbon steel into the low-carbon iron, creating a carbon concentration gradient. This likely led to partial martensitic transformation in areas near the ferrite interface.

With this foundational knowledge of Japanese kitchen knives, we now turn our attention to the katana itself.

As tradition suggests, is it really constructed through the combination of different materials and the control of cooling rates? Let’s investigate the internal structure of the katana and see what the evidence reveals.

Analyzing the Microstructure of the Japanese Katana

Structural Analysis of Four Japanese Swords

Let’s now examine the macrostructure and microstructure of authentic katanas.

This study analyzed the internal composition of the following four katanas:

| Smith | Year Forged | Distance from Hamachi (mm) | Notes |

|---|---|---|---|

| 備州長舩政光/Bishū Osafune Masamitsu | 1382 | 30 | Heavily polished; part of the shingane (core steel) is exposed |

| 近江大掾藤原忠廣/Ōmi Daijō Fujiwara Tadahiro | 1678 | 190 | Rated as Ō-wazamono (exceptionally sharp) |

| 奥和泉守忠重/Oku Izumi no Kami Tadashige | 1657~1720 | 90 | Rated as Ryō-wazamono (very sharp) |

| 平安城藤原國継/Heianjō Fujiwara Kunitsugu | 1656 | 200 | Noted for a coarse grain pattern |

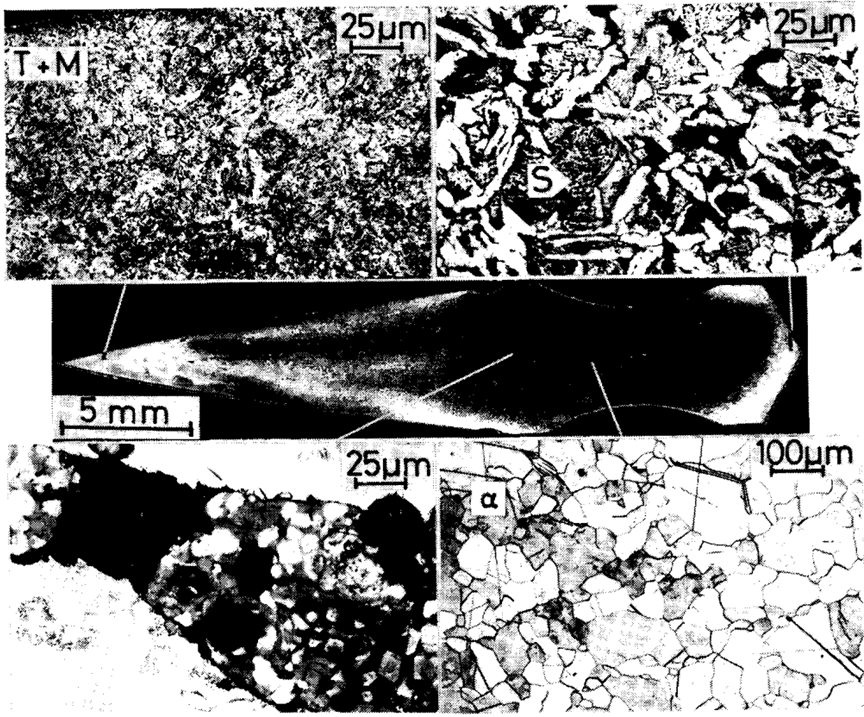

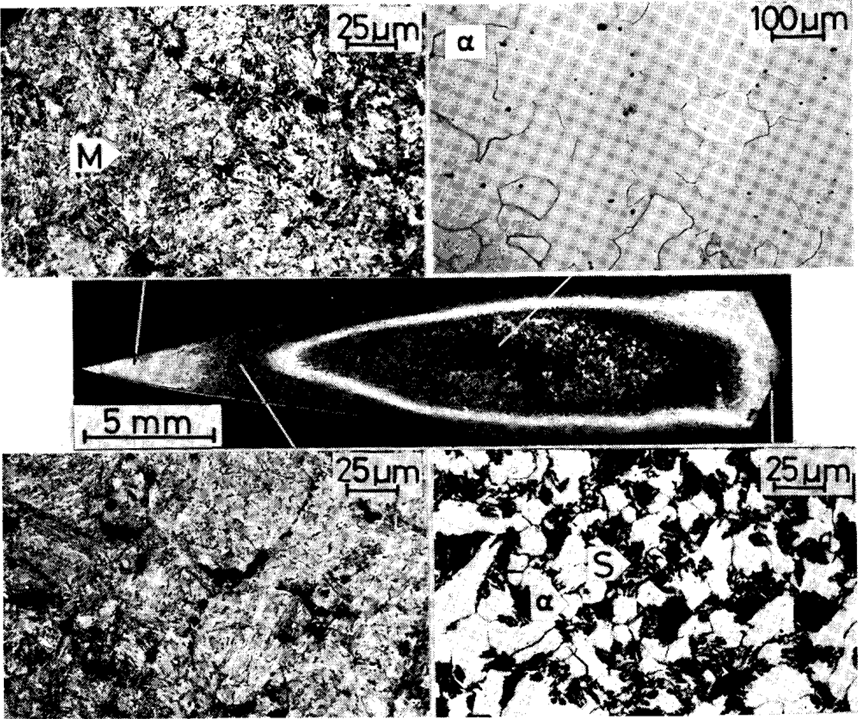

Masamitsu — Macro & Microstructure

T = Troostite

M = Martensite

S = Sorbite

α = Ferrite

The edge consists of martensite, transitioning to a region of troostite + martensite, and eventually becoming rich in ferrite deeper into the blade.

In the core (shingane), very little pearlite is observed, indicating a low-carbon composition. Toward the mune (spine), the structure returns to a high-carbon phase, showing a mixture of ferrite and sorbite.

This structure—martensitic edge, ferritic core, and a spine composed of ferrite and sorbite—is a textbook example of the traditional Japanese katana’s metallurgical design.

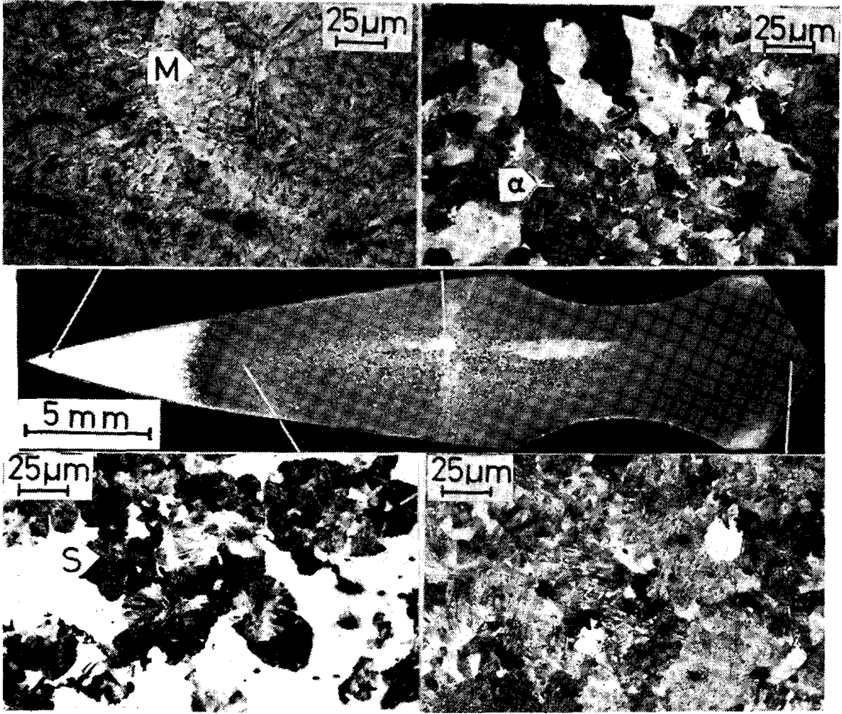

Tadahiro — Macro & Microstructure

The edge region shows martensite, the side shows troostite, the core consists of ferrite, and the spine is composed of sorbite.

This well-defined separation demonstrates a classic example of an ideal katana structure.

Tadashige — Macro & Microstructure

While the edge region is composed of martensite, its needle-like structure is coarser compared to the others.

Beneath that lies sorbite, and in the macrostructure, a white region is visible near the center, which likely corresponds to pearlite containing interspersed ferrite.

Once again, the structure transitions from a hard martensitic edge to a softer sorbitic spine—illustrating the well-balanced hardness gradient typical of the Japanese sword.

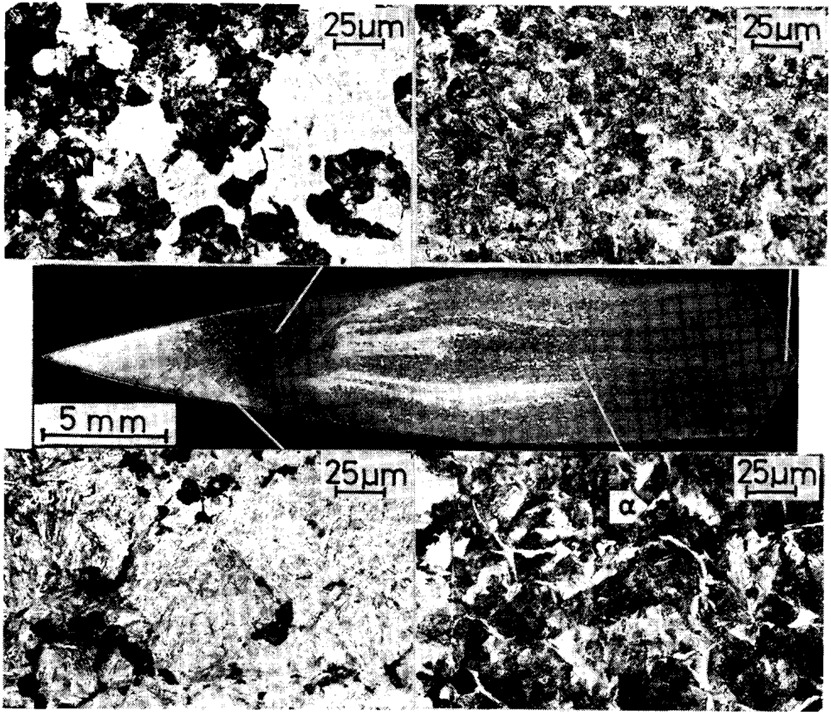

Kunitsugu — Macro & Microstructure

The macrostructure shows a dark region near the edge rich in troostite, but no significant structural changes were observed on either side of this area.

Overall, the steel appears to be high-carbon, with the center containing a pearlitic structure with some ferrite, while the spine lacks ferrite altogether.

In this case, we did not observe the typical gradient in structure and hardness from edge to spine that characterizes most Japanese swords.

So far, we’ve examined the internal structure of the Japanese katana.

Next, we’ll explore the carbon content and how it varies throughout the blade.

Carbon Content and Hardness Distribution in Different Sections of the Katana

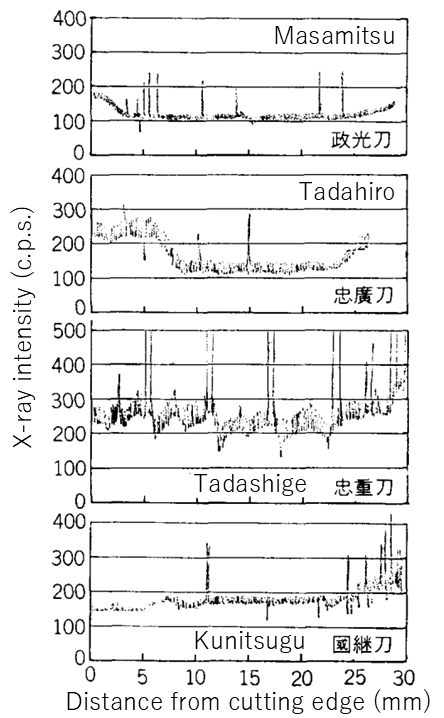

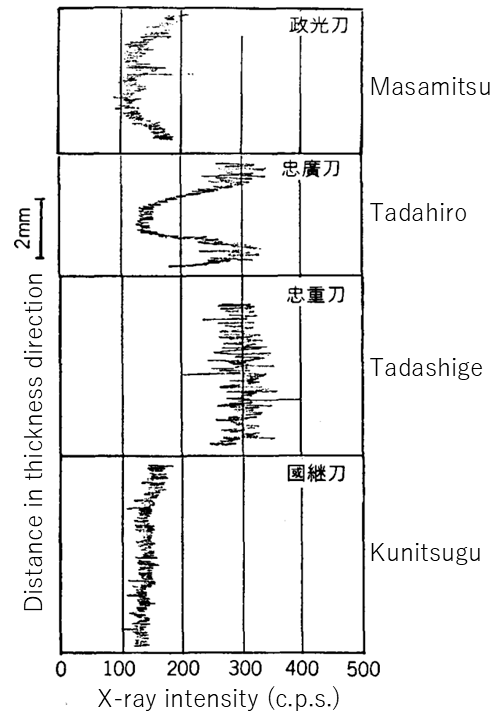

To analyze the carbon content in various parts of each sword, X-ray analysis was conducted. Since higher X-ray intensity corresponds to higher carbon content, this method allows us to visualize the carbon distribution across the blade.

The results are summarized below:

Masamitsu

Edge (hagane): ~170 cps

Core (shingane): ~110 cps

Spine (mune): ~150 cps

Overall, Masamitsu exhibits a lower-carbon composition compared to the other swords. The high-carbon edge layer extends only 2–3 mm from the blade tip, which is relatively short.

However, structurally, it clearly demonstrates the classic Japanese sword design, in which a soft core is enclosed by harder steel at the edge and spine.

Tadahiro

Edge: ~250 cps

Core: ~125 cps

Spine: ~200 cps

Each region is clearly differentiated, and the outer jacket shows particularly high carbon content. The edge layer extends approximately 6 mm, making it notably thick.

This sword is an ideal example of traditional katana construction, with a soft core protected by harder outer steel—exemplary for understanding the metallurgical principles behind Japanese swords.

Tadashige

This sword shows a consistently high carbon content throughout, with minimal variation between the edge and core.

Additionally, repetitive fluctuations in carbon levels occur every 2–3 mm, which are likely the traces of repeated folding and forging (orikaeshi-tanren).

Kunitsugu

Carbon content increases toward the spine, but no significant difference in carbon levels is seen between the core and outer jacket.

This suggests a structure that deviates from the traditional Japanese method of combining soft and hard steels.

Forged to Perfection: The Hidden Science Behind the Katana

The Japanese katana is the result of a remarkably sophisticated manufacturing process—combining multiple types of steel with precise control of cooling rates.

Thanks to this process, the blade edge transforms into martensite, while the spine develops structures such as pearlite, cementite, and ferrite. This complex microstructure is what allows the katana to achieve the legendary trifecta: unbreakable, unbending, and razor-sharp—a combination unmatched by any other blade in the world.

There has long been a question: Does the final product truly reflect this intended structure?

Through this analysis, we were able to confirm that, indeed, the blade edge consists of martensite, while the spine shows pearlite, cementite, and ferrite—precisely what traditional swordsmithing techniques aim to achieve.

Carbon distribution analysis further revealed that swords like Masamitsu and Tadahiro clearly demonstrate a composite structure, with a low-carbon core enclosed by high-carbon edge and jacket layers—a textbook example of classic katana construction.

Tadashige, by contrast, appeared to be made from folded layers of high- and low-carbon steel—a technique reminiscent of Damascus steel. While the method differs slightly, the resulting structure still performs within the expectations of a high-quality Japanese blade.

On the other hand, Kunitsugu showed a unique profile: carbon content increased toward the spine, and there was no clear distinction in carbon levels between the core and outer layers. This suggests a microstructure that deviates from traditional expectations, though of course, this result applies only to this specific sword—each katana must be considered individually.

For those passionate about Japanese swords, it would be fascinating to examine the internal structure of every blade during appreciation.

Of course, it’s not feasible to cut open such precious artifacts for scientific study. But perhaps one of the greatest joys of collecting and admiring katanas is the sense of wonder—the question:

“What might be happening inside this blade?”

In that mystery lies part of the katana’s enduring allure.

References

Toshio Kato, Kentaro Asakura(2013). 刃物あれこれ

Tsuneo Takahashi, Takeshi Murakami, Senri Okada and Norihisa Fujii(1985). Discovering New Aspects in a Japanese Sword